Photo catalystic steel plate roof

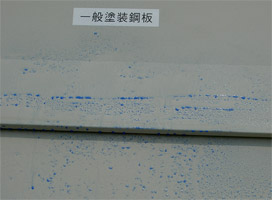

Water poured over a sheet-iron roof normally breaks into globular drops. But water poured over sheet-iron coated with oxidized titanium, an optical catalyst, forms a thin film because of its diminished surface tension. The resulting accelerated evaporation by sunlight consumes more ambient latent heat, thus more quickly lowering the temperature beneath the roof.

The Japan Pavilion is conducting an experiment with this mechanism, with the goal of determining the optimal amount of water poured over the roof - to be regulated according to sunlight intensity - for maximizing the heat of vaporization. Measurements and data obtained in the experiment will be announced publicly.

Optical catalysis is a resolution in reaction to optical energy, with oxidized titanium serving as the catalyst. The oxidized titanium itself is unchanged, so remains serviceable almost permanently and in any environment, as long as ultraviolet rays can be harnessed. It is also a clean material, generating no waste in the process. The optical catalyst’s functions include: (1) atmospheric purification, (2) deodorization, (3) water purification, (4) anti-bacterial coating and (5) anti-soiling surface protection. In addition, oxidized titanium is safe for humans, as evidenced by its use as a chocolate coating. The environment-friendly attributes of this substance are increasingly a focus of attention.

Optical catalyst-coated roof under construction

Water-pouring experiment

Ordinarily-coated sheet iron (globular water drops)

Optical catalyst-coated sheet iron (no water drops)